Pipli, Kurukshetra, Haryana

- GST NO. : 06AADCF2891C1ZV

Industrial Gearbox

Leading Manufacturers, Exporters, Wholesaler, Trader and Importer of Aluminium Worm Gearbox, Aluminum Worm Gearbox, Bevel Gearbox, Conveyor Gearbox, Crane Duty Gearbox, Double Reduction Gearbox, Gear Box and NMRV Worm Gearbox from Kurukshetra.

| Business Type | Manufacturer, Exporter, Supplier, Trader |

| Brand Name | M Power Transmission |

| Material | Aluminum |

| Driven Type | Electric |

| Color | Grey |

| Pressure | High Pressure |

| Motor Power | 3-5hp |

| Packaging Type | Wooden Box |

| Specialities | Rust Proof, High Performance |

| Type | Worm Gearbox |

| Weight | 10 KG |

| Country of Origin | India |

| Port | Delhi |

| Payment Terms | L/C, T/T |

| Delivery Time | 1 Week |

The gearbox for industrial use is a robust and versatile mechanical device specially designed to transfer power from a prime mover, such as an electric motor or an internal combustion engine, to various machines and equipment in industrial settings. It is an essential component that plays a key role in enhancing the efficiency, reliability, and productivity of industrial processes.

These gearboxes are built to withstand heavy loads, high torques, and extreme operating conditions commonly found in industrial environments. They are crafted from durable materials such as cast iron or high-grade steel, ensuring long-lasting performance and resistance to wear and tear. The gearbox also incorporates advanced engineering techniques, including precise machining, heat treatment, and surface finishing, to further enhance its strength and durability.

One of the primary functions of the industrial gearbox is to provide speed reduction or increase, allowing the machinery to operate at the desired speed for specific applications. The gearbox achieves this by utilizing various gear ratios and gear configurations, translating the high-speed input from the prime mover into the appropriate speed required by the industrial equipment.

In addition to speed reduction or increase, industrial gearboxes also provide torque multiplication, enabling the machinery to generate sufficient force to handle heavy workloads. This torque multiplication is achieved through the precise meshing of gears within the gearbox, efficiently transferring power from the prime mover to the load.

Furthermore, the industrial gearbox ensures precise and smooth power transmission, minimizing energy losses and maximizing overall efficiency. It is equipped with high-precision gears and shafts, as well as advanced lubrication and cooling systems, to reduce friction, dissipate heat, and maintain optimal operating conditions. This results in improved energy efficiency, reduced maintenance requirements, and extended equipment lifespan.

Industrial gearboxes are available in various types and configurations to cater to different industrial applications. Common types include spur gearboxes, helical gearboxes, bevel gearboxes, worm gearboxes, and planetary gearboxes. Each type possesses unique characteristics, such as gear arrangements, torque capacity, noise levels, and efficiency, making them suitable for specific industrial processes and machinery.

Safety is another crucial aspect of industrial gearboxes. They often incorporate safety features like overload protection devices, temperature sensors, and emergency stop systems to ensure safe operation, prevent damage to the equipment, and protect personnel working in the vicinity.

Moreover, modern industrial gearboxes are designed with flexibility in mind. They can be easily adapted to different mounting orientations, allowing them to be integrated into diverse machinery layouts. The modular construction of these gearboxes also enables easy maintenance and repair, as individual components can be replaced or serviced without the need for extensive dismantling.

In summary, the gearbox for industrial use is a vital component in industrial machinery and equipment. It provides speed reduction or increase, torque multiplication, and precise power transmission, ensuring efficient and reliable operation in demanding industrial environments. With their durability, versatility, and safety features, these gearboxes play a critical role in optimizing industrial processes and enhancing productivity in a wide range of industries.

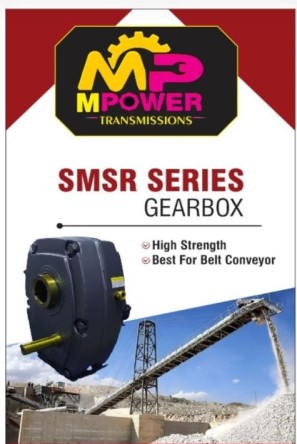

| Business Type | Manufacturer, Exporter, Supplier, Trader |

| Brand Name | M Power Transmission |

| Material | Cast Iron |

| Finishing | Powder Coated |

| Driven Type | Electric |

| Gear Type | Helical |

| Color | Grey |

| Motor Power | 3-5hp, 7-10hp |

| Usage | Conveyor, Robotics, Pharmaceutical Machinery, Food Packaging Machinery, Chemical Machinery |

| Style | Horizontal |

| Packaging Type | Wooden Box |

| Mounting Type | Flange |

| Specialities | Rust Proof, Long Life, High Performance, Easy To Operate |

| Dimension (LxWxH) | 580x260x465mm |

| Type | Worm Gearbox |

| Weight | 100-200 Kg |

| Warranty | 1 Year |

| Country of Origin | India |

| Input Speed | 700rpm |

| Corrosion Resistance | Yes |

| Witdh | 50-80mm, 80-120mm, 120-150mm |

| Port | Delhi |

| Payment Terms | L/C, T/T |

| Delivery Time | 1 Week |

The gearbox for industrial use is a robust and versatile mechanical device specially designed to transfer power from a prime mover, such as an electric motor or an internal combustion engine, to various machines and equipment in industrial settings. It is an essential component that plays a key role in enhancing the efficiency, reliability, and productivity of industrial processes.

These gearboxes are built to withstand heavy loads, high torques, and extreme operating conditions commonly found in industrial environments. They are crafted from durable materials such as cast iron or high-grade steel, ensuring long-lasting performance and resistance to wear and tear. The gearbox also incorporates advanced engineering techniques, including precise machining, heat treatment, and surface finishing, to further enhance its strength and durability.

One of the primary functions of the industrial gearbox is to provide speed reduction or increase, allowing the machinery to operate at the desired speed for specific applications. The gearbox achieves this by utilizing various gear ratios and gear configurations, translating the high-speed input from the prime mover into the appropriate speed required by the industrial equipment.

In addition to speed reduction or increase, industrial gearboxes also provide torque multiplication, enabling the machinery to generate sufficient force to handle heavy workloads. This torque multiplication is achieved through the precise meshing of gears within the gearbox, efficiently transferring power from the prime mover to the load.

Furthermore, the industrial gearbox ensures precise and smooth power transmission, minimizing energy losses and maximizing overall efficiency. It is equipped with high-precision gears and shafts, as well as advanced lubrication and cooling systems, to reduce friction, dissipate heat, and maintain optimal operating conditions. This results in improved energy efficiency, reduced maintenance requirements, and extended equipment lifespan.

Industrial gearboxes are available in various types and configurations to cater to different industrial applications. Common types include spur gearboxes, helical gearboxes, bevel gearboxes, worm gearboxes, and planetary gearboxes. Each type possesses unique characteristics, such as gear arrangements, torque capacity, noise levels, and efficiency, making them suitable for specific industrial processes and machinery.

Safety is another crucial aspect of industrial gearboxes. They often incorporate safety features like overload protection devices, temperature sensors, and emergency stop systems to ensure safe operation, prevent damage to the equipment, and protect personnel working in the vicinity.

Moreover, modern industrial gearboxes are designed with flexibility in mind. They can be easily adapted to different mounting orientations, allowing them to be integrated into diverse machinery layouts. The modular construction of these gearboxes also enables easy maintenance and repair, as individual components can be replaced or serviced without the need for extensive dismantling.

In summary, the gearbox for industrial use is a vital component in industrial machinery and equipment. It provides speed reduction or increase, torque multiplication, and precise power transmission, ensuring efficient and reliable operation in demanding industrial environments. With their durability, versatility, and safety features, these gearboxes play a critical role in optimizing industrial processes and enhancing productivity in a wide range of industries.

| Business Type | Manufacturer, Exporter, Supplier, Trader |

| Material | Cast Iron |

| Brand Name | M Power Transmission |

| Gear Type | Helical |

| Finishing | Powder Coated |

| Driven Type | Electric |

| Color | Blue |

| Condition | New |

| Power Rate | 9-12 Kw |

| Usage | Conveyor, Robotics, Pharmaceutical Machinery, Food Packaging Machinery, Chemical Machinery |

| Mounting Type | Flange |

| Voltage | 440V |

| Specialities | Rust Proof, Long Life, High Performance, Easy To Operate |

| Dimension (LxWxH) | 275x90x285mm |

| Packaging Type | Wooden Box |

| Hardness | 58 Hrc |

| Country of Origin | India |

| Corrosion Resistance | Yes |

| Warranty | 1 Year |

| Input Speed | 700rpm |

| Weight | 100-200 Kg |

| Witdh | 50-80mm |

| Running Noise | 50 DB |

| Port | Delhi |

| Payment Terms | L/C, T/T |

| Delivery Time | 1 Week |

The gearbox for industrial use is a robust and versatile mechanical device specially designed to transfer power from a prime mover, such as an electric motor or an internal combustion engine, to various machines and equipment in industrial settings. It is an essential component that plays a key role in enhancing the efficiency, reliability, and productivity of industrial processes.

These gearboxes are built to withstand heavy loads, high torques, and extreme operating conditions commonly found in industrial environments. They are crafted from durable materials such as cast iron or high-grade steel, ensuring long-lasting performance and resistance to wear and tear. The gearbox also incorporates advanced engineering techniques, including precise machining, heat treatment, and surface finishing, to further enhance its strength and durability.

One of the primary functions of the industrial gearbox is to provide speed reduction or increase, allowing the machinery to operate at the desired speed for specific applications. The gearbox achieves this by utilizing various gear ratios and gear configurations, translating the high-speed input from the prime mover into the appropriate speed required by the industrial equipment.

In addition to speed reduction or increase, industrial gearboxes also provide torque multiplication, enabling the machinery to generate sufficient force to handle heavy workloads. This torque multiplication is achieved through the precise meshing of gears within the gearbox, efficiently transferring power from the prime mover to the load.

Furthermore, the industrial gearbox ensures precise and smooth power transmission, minimizing energy losses and maximizing overall efficiency. It is equipped with high-precision gears and shafts, as well as advanced lubrication and cooling systems, to reduce friction, dissipate heat, and maintain optimal operating conditions. This results in improved energy efficiency, reduced maintenance requirements, and extended equipment lifespan.

Industrial gearboxes are available in various types and configurations to cater to different industrial applications. Common types include spur gearboxes, helical gearboxes, bevel gearboxes, worm gearboxes, and planetary gearboxes. Each type possesses unique characteristics, such as gear arrangements, torque capacity, noise levels, and efficiency, making them suitable for specific industrial processes and machinery.

Safety is another crucial aspect of industrial gearboxes. They often incorporate safety features like overload protection devices, temperature sensors, and emergency stop systems to ensure safe operation, prevent damage to the equipment, and protect personnel working in the vicinity.

Moreover, modern industrial gearboxes are designed with flexibility in mind. They can be easily adapted to different mounting orientations, allowing them to be integrated into diverse machinery layouts. The modular construction of these gearboxes also enables easy maintenance and repair, as individual components can be replaced or serviced without the need for extensive dismantling.

In summary, the gearbox for industrial use is a vital component in industrial machinery and equipment. It provides speed reduction or increase, torque multiplication, and precise power transmission, ensuring efficient and reliable operation in demanding industrial environments. With their durability, versatility, and safety features, these gearboxes play a critical role in optimizing industrial processes and enhancing productivity in a wide range of industries.

| Business Type | Manufacturer, Exporter, Supplier, Trader |

| Brand Name | M Power Transmissions |

| Material | Cast Iron |

| Warranty | 1 Year |

| Country of Origin | India |

| Color | Black |

| Power | 3 HP |

| Voltage (Volt) | 220V |

| Frequency | 50-60Hz |

| Port | Delhi |

| Payment Terms | L/C, T/T |

| Delivery Time | 1 Week |

The gearbox for industrial use is a robust and versatile mechanical device specially designed to transfer power from a prime mover, such as an electric motor or an internal combustion engine, to various machines and equipment in industrial settings. It is an essential component that plays a key role in enhancing the efficiency, reliability, and productivity of industrial processes.

These gearboxes are built to withstand heavy loads, high torques, and extreme operating conditions commonly found in industrial environments. They are crafted from durable materials such as cast iron or high-grade steel, ensuring long-lasting performance and resistance to wear and tear. The gearbox also incorporates advanced engineering techniques, including precise machining, heat treatment, and surface finishing, to further enhance its strength and durability.

One of the primary functions of the industrial gearbox is to provide speed reduction or increase, allowing the machinery to operate at the desired speed for specific applications. The gearbox achieves this by utilizing various gear ratios and gear configurations, translating the high-speed input from the prime mover into the appropriate speed required by the industrial equipment.

In addition to speed reduction or increase, industrial gearboxes also provide torque multiplication, enabling the machinery to generate sufficient force to handle heavy workloads. This torque multiplication is achieved through the precise meshing of gears within the gearbox, efficiently transferring power from the prime mover to the load.

Furthermore, the industrial gearbox ensures precise and smooth power transmission, minimizing energy losses and maximizing overall efficiency. It is equipped with high-precision gears and shafts, as well as advanced lubrication and cooling systems, to reduce friction, dissipate heat, and maintain optimal operating conditions. This results in improved energy efficiency, reduced maintenance requirements, and extended equipment lifespan.

Industrial gearboxes are available in various types and configurations to cater to different industrial applications. Common types include spur gearboxes, helical gearboxes, bevel gearboxes, worm gearboxes, and planetary gearboxes. Each type possesses unique characteristics, such as gear arrangements, torque capacity, noise levels, and efficiency, making them suitable for specific industrial processes and machinery.

Safety is another crucial aspect of industrial gearboxes. They often incorporate safety features like overload protection devices, temperature sensors, and emergency stop systems to ensure safe operation, prevent damage to the equipment, and protect personnel working in the vicinity.

Moreover, modern industrial gearboxes are designed with flexibility in mind. They can be easily adapted to different mounting orientations, allowing them to be integrated into diverse machinery layouts. The modular construction of these gearboxes also enables easy maintenance and repair, as individual components can be replaced or serviced without the need for extensive dismantling.

In summary, the gearbox for industrial use is a vital component in industrial machinery and equipment. It provides speed reduction or increase, torque multiplication, and precise power transmission, ensuring efficient and reliable operation in demanding industrial environments. With their durability, versatility, and safety features, these gearboxes play a critical role in optimizing industrial processes and enhancing productivity in a wide range of industries.

| Business Type | Manufacturer, Exporter, Supplier, Trader |

| Brand Name | M Power Transmission |

| Material | Cast Iron |

| Finishing | Polished |

| Driven Type | Electric |

| Gear Type | Helical |

| Color | Blue |

| Condition | New |

| Motor Power | 1-3hp |

| Power Rate | 9-12 Kw |

| Usage | Conveyor, Robotics, Pharmaceutical Machinery, Food Packaging Machinery, Chemical Machinery |

| Style | Vertical |

| Packaging Type | Carton Box, Wooden Box, Metal Sheet Box |

| Specialities | Rust Proof, Long Life, High Performance, Easy To Operate |

| Dimension (LxWxH) | 275x90x285mm |

| Type | Crane Duty Gearbox |

| Weight | 100-200 Kg |

| Warranty | 1 Year |

| Country of Origin | India |

| Input Speed | 700rpm |

| Orientation | Vertical |

| Corrosion Resistance | Yes |

| Port | Delhi |

| Payment Terms | L/C, T/T |

| Delivery Time | 1 Week |

The gearbox for industrial use is a robust and versatile mechanical device specially designed to transfer power from a prime mover, such as an electric motor or an internal combustion engine, to various machines and equipment in industrial settings. It is an essential component that plays a key role in enhancing the efficiency, reliability, and productivity of industrial processes.

These gearboxes are built to withstand heavy loads, high torques, and extreme operating conditions commonly found in industrial environments. They are crafted from durable materials such as cast iron or high-grade steel, ensuring long-lasting performance and resistance to wear and tear. The gearbox also incorporates advanced engineering techniques, including precise machining, heat treatment, and surface finishing, to further enhance its strength and durability.

One of the primary functions of the industrial gearbox is to provide speed reduction or increase, allowing the machinery to operate at the desired speed for specific applications. The gearbox achieves this by utilizing various gear ratios and gear configurations, translating the high-speed input from the prime mover into the appropriate speed required by the industrial equipment.

In addition to speed reduction or increase, industrial gearboxes also provide torque multiplication, enabling the machinery to generate sufficient force to handle heavy workloads. This torque multiplication is achieved through the precise meshing of gears within the gearbox, efficiently transferring power from the prime mover to the load.

Furthermore, the industrial gearbox ensures precise and smooth power transmission, minimizing energy losses and maximizing overall efficiency. It is equipped with high-precision gears and shafts, as well as advanced lubrication and cooling systems, to reduce friction, dissipate heat, and maintain optimal operating conditions. This results in improved energy efficiency, reduced maintenance requirements, and extended equipment lifespan.

Industrial gearboxes are available in various types and configurations to cater to different industrial applications. Common types include spur gearboxes, helical gearboxes, bevel gearboxes, worm gearboxes, and planetary gearboxes. Each type possesses unique characteristics, such as gear arrangements, torque capacity, noise levels, and efficiency, making them suitable for specific industrial processes and machinery.

Safety is another crucial aspect of industrial gearboxes. They often incorporate safety features like overload protection devices, temperature sensors, and emergency stop systems to ensure safe operation, prevent damage to the equipment, and protect personnel working in the vicinity.

Moreover, modern industrial gearboxes are designed with flexibility in mind. They can be easily adapted to different mounting orientations, allowing them to be integrated into diverse machinery layouts. The modular construction of these gearboxes also enables easy maintenance and repair, as individual components can be replaced or serviced without the need for extensive dismantling.

In summary, the gearbox for industrial use is a vital component in industrial machinery and equipment. It provides speed reduction or increase, torque multiplication, and precise power transmission, ensuring efficient and reliable operation in demanding industrial environments. With their durability, versatility, and safety features, these gearboxes play a critical role in optimizing industrial processes and enhancing productivity in a wide range of industries.

| Business Type | Manufacturer, Exporter, Supplier, Trader |

| Brand Name | M Power Transmission |

| Material | Aluminum |

| Finishing | Powder Coated |

| Driven Type | Electric |

| Gear Type | Worm |

| Color | Grey |

| Motor Power | 5-7hp |

| Power Rate | 3-6 Kw |

| Application | Conveyor, Robotics, Pharmaceutical Machinery, Food Packaging Machinery, Chemical Machinery |

| Style | Vertical |

| Packaging Type | Wooden Box |

| Mounting Type | Flange |

| Specialities | Rust Proof, Long Life, High Performance, Easy To Operate |

| Dimension (LxWxH) | 275x90x285mm |

| Type | WORM TYPE |

| Weight | 500-600 Kg |

| Warranty | 1 Year |

| Country of Origin | India |

| Input Speed | 1400rpm |

| Corrosion Resistance | Yes |

| Witdh | 50-80mm |

| Port | Delhi |

| Payment Terms | L/C, T/T |

| Delivery Time | 1 Week |

The gearbox for industrial use is a robust and versatile mechanical device specially designed to transfer power from a prime mover, such as an electric motor or an internal combustion engine, to various machines and equipment in industrial settings. It is an essential component that plays a key role in enhancing the efficiency, reliability, and productivity of industrial processes.

These gearboxes are built to withstand heavy loads, high torques, and extreme operating conditions commonly found in industrial environments. They are crafted from durable materials such as cast iron or high-grade steel, ensuring long-lasting performance and resistance to wear and tear. The gearbox also incorporates advanced engineering techniques, including precise machining, heat treatment, and surface finishing, to further enhance its strength and durability.

One of the primary functions of the industrial gearbox is to provide speed reduction or increase, allowing the machinery to operate at the desired speed for specific applications. The gearbox achieves this by utilizing various gear ratios and gear configurations, translating the high-speed input from the prime mover into the appropriate speed required by the industrial equipment.

In addition to speed reduction or increase, industrial gearboxes also provide torque multiplication, enabling the machinery to generate sufficient force to handle heavy workloads. This torque multiplication is achieved through the precise meshing of gears within the gearbox, efficiently transferring power from the prime mover to the load.

Furthermore, the industrial gearbox ensures precise and smooth power transmission, minimizing energy losses and maximizing overall efficiency. It is equipped with high-precision gears and shafts, as well as advanced lubrication and cooling systems, to reduce friction, dissipate heat, and maintain optimal operating conditions. This results in improved energy efficiency, reduced maintenance requirements, and extended equipment lifespan.

Industrial gearboxes are available in various types and configurations to cater to different industrial applications. Common types include spur gearboxes, helical gearboxes, bevel gearboxes, worm gearboxes, and planetary gearboxes. Each type possesses unique characteristics, such as gear arrangements, torque capacity, noise levels, and efficiency, making them suitable for specific industrial processes and machinery

Safety is another crucial aspect of industrial gearboxes. They often incorporate safety features like overload protection devices, temperature sensors, and emergency stop systems to ensure safe operation, prevent damage to the equipment, and protect personnel working in the vicinity.

Moreover, modern industrial gearboxes are designed with flexibility in mind. They can be easily adapted to different mounting orientations, allowing them to be integrated into diverse machinery layouts. The modular construction of these gearboxes also enables easy maintenance and repair, as individual components can be replaced or serviced without the need for extensive dismantling.

In summary, the gearbox for industrial use is a vital component in industrial machinery and equipment. It provides speed reduction or increase, torque multiplication, and precise power transmission, ensuring efficient and reliable operation in demanding industrial environments. With their durability, versatility, and safety features, these gearboxes play a critical role in optimizing industrial processes and enhancing productivity in a wide range of industries.

| Business Type | Manufacturer, Exporter, Supplier, Trader |

| Brand Name | M Power Transmissions |

| Material | Cast Iron |

| Finishing | Polished |

| Driven Type | Electric |

| Gear Type | Ground |

| Color | Blue |

| Usage | Conveyor, Robotics, Pharmaceutical Machinery, Food Packaging Machinery, Chemical Machinery |

| Packaging Type | Carton Box |

| Mounting Type | Foot |

| Feature | Rust Proof, Long Life, High Performance, Easy To Operate |

| Dimension (LxWxH) | 275x90x285mm |

| Warranty | 1 Year |

| Country of Origin | India |

| Input Speed | 700rpm |

| Port | Delhi |

| Payment Terms | L/C, T/T |

| Delivery Time | 1 Week |

The gearbox for industrial use is a robust and versatile mechanical device specially designed to transfer power from a prime mover, such as an electric motor or an internal combustion engine, to various machines and equipment in industrial settings. It is an essential component that plays a key role in enhancing the efficiency, reliability, and productivity of industrial processes.

These gearboxes are built to withstand heavy loads, high torques, and extreme operating conditions commonly found in industrial environments. They are crafted from durable materials such as cast iron or high-grade steel, ensuring long-lasting performance and resistance to wear and tear. The gearbox also incorporates advanced engineering techniques, including precise machining, heat treatment, and surface finishing, to further enhance its strength and durability.

One of the primary functions of the industrial gearbox is to provide speed reduction or increase, allowing the machinery to operate at the desired speed for specific applications. The gearbox achieves this by utilizing various gear ratios and gear configurations, translating the high-speed input from the prime mover into the appropriate speed required by the industrial equipment.

In addition to speed reduction or increase, industrial gearboxes also provide torque multiplication, enabling the machinery to generate sufficient force to handle heavy workloads. This torque multiplication is achieved through the precise meshing of gears within the gearbox, efficiently transferring power from the prime mover to the load.

Furthermore, the industrial gearbox ensures precise and smooth power transmission, minimizing energy losses and maximizing overall efficiency. It is equipped with high-precision gears and shafts, as well as advanced lubrication and cooling systems, to reduce friction, dissipate heat, and maintain optimal operating conditions. This results in improved energy efficiency, reduced maintenance requirements, and extended equipment lifespan.

Industrial gearboxes are available in various types and configurations to cater to different industrial applications. Common types include spur gearboxes, helical gearboxes, bevel gearboxes, worm gearboxes, and planetary gearboxes. Each type possesses unique characteristics, such as gear arrangements, torque capacity, noise levels, and efficiency, making them suitable for specific industrial processes and machinery.

Safety is another crucial aspect of industrial gearboxes. They often incorporate safety features like overload protection devices, temperature sensors, and emergency stop systems to ensure safe operation, prevent damage to the equipment, and protect personnel working in the vicinity.

Moreover, modern industrial gearboxes are designed with flexibility in mind. They can be easily adapted to different mounting orientations, allowing them to be integrated into diverse machinery layouts. The modular construction of these gearboxes also enables easy maintenance and repair, as individual components can be replaced or serviced without the need for extensive dismantling.

In summary, the gearbox for industrial use is a vital component in industrial machinery and equipment. It provides speed reduction or increase, torque multiplication, and precise power transmission, ensuring efficient and reliable operation in demanding industrial environments. With their durability, versatility, and safety features, these gearboxes play a critical role in optimizing industrial processes and enhancing productivity in a wide range of industries.

| Business Type | Manufacturer, Exporter, Supplier, Trader |

| Brand Name | M Power Transmissions |

| Finishing | Powder Coated |

| Driven Type | Electric |

| Gear Type | Worm |

| Color | Grey |

| Motor Power | 1-3hp, 3-5hp, 5-7hp, 7-10hp |

| Usage | Conveyor, Robotics, Pharmaceutical Machinery, Food Packaging Machinery, Chemical Machinery |

| Packaging Type | Carton Box |

| Mounting Type | Flange |

| Specialities | Rust Proof, Long Life, High Performance, Easy To Operate |

| Dimension (LxWxH) | 275x90x285mm |

| Warranty | 1 Year |

| Country of Origin | India |

| Input Speed | 1400rpm |

| Corrosion Resistance | Yes |

| Witdh | 50-80mm, 80-120mm, 120-150mm |

| Payment Terms | L/C, T/T |

The gearbox for industrial use is a robust and versatile mechanical device specially designed to transfer power from a prime mover, such as an electric motor or an internal combustion engine, to various machines and equipment in industrial settings. It is an essential component that plays a key role in enhancing the efficiency, reliability, and productivity of industrial processes.

These gearboxes are built to withstand heavy loads, high torques, and extreme operating conditions commonly found in industrial environments. They are crafted from durable materials such as cast iron or high-grade steel, ensuring long-lasting performance and resistance to wear and tear. The gearbox also incorporates advanced engineering techniques, including precise machining, heat treatment, and surface finishing, to further enhance its strength and durability.

One of the primary functions of the industrial gearbox is to provide speed reduction or increase, allowing the machinery to operate at the desired speed for specific applications. The gearbox achieves this by utilizing various gear ratios and gear configurations, translating the high-speed input from the prime mover into the appropriate speed required by the industrial equipment.

In addition to speed reduction or increase, industrial gearboxes also provide torque multiplication, enabling the machinery to generate sufficient force to handle heavy workloads. This torque multiplication is achieved through the precise meshing of gears within the gearbox, efficiently transferring power from the prime mover to the load.

Furthermore, the industrial gearbox ensures precise and smooth power transmission, minimizing energy losses and maximizing overall efficiency. It is equipped with high-precision gears and shafts, as well as advanced lubrication and cooling systems, to reduce friction, dissipate heat, and maintain optimal operating conditions. This results in improved energy efficiency, reduced maintenance requirements, and extended equipment lifespan.

Industrial gearboxes are available in various types and configurations to cater to different industrial applications. Common types include spur gearboxes, helical gearboxes, bevel gearboxes, worm gearboxes, and planetary gearboxes. Each type possesses unique characteristics, such as gear arrangements, torque capacity, noise levels, and efficiency, making them suitable for specific industrial processes and machinery.

Safety is another crucial aspect of industrial gearboxes. They often incorporate safety features like overload protection devices, temperature sensors, and emergency stop systems to ensure safe operation, prevent damage to the equipment, and protect personnel working in the vicinity.

Moreover, modern industrial gearboxes are designed with flexibility in mind. They can be easily adapted to different mounting orientations, allowing them to be integrated into diverse machinery layouts. The modular construction of these gearboxes also enables easy maintenance and repair, as individual components can be replaced or serviced without the need for extensive dismantling.

In summary, the gearbox for industrial use is a vital component in industrial machinery and equipment. It provides speed reduction or increase, torque multiplication, and precise power transmission, ensuring efficient and reliable operation in demanding industrial environments. With their durability, versatility, and safety features, these gearboxes play a critical role in optimizing industrial processes and enhancing productivity in a wide range of industries.